- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China PV Inverter and Energy Storage Manufacturers, Suppliers, Factory

The PV Inverter and Energy Storage container energy storage system (CESS) is an integrated energy storage system developed to meet the needs of the mobile energy storage market. It integrates battery cabinets, lithium battery management systems (BMS), and container dynamic environment monitoring systems, and can integrate storage according to customer needs. energy converters and energy management systems. The container energy storage system has the characteristics of simplified infrastructure construction costs, short construction period, high degree of modularity, and easy transportation and installation. It can be applied to thermal, wind, solar and other power stations or islands, communities, schools, scientific research institutions, factories, large Load centers and other applications.

PV Inverter and Energy Storage container is two industry, one is PV Inverter industry, another one is Energy Storage container.The photovoltaic system converts solar energy into electrical energy, and the energy storage system stores the electrical energy generated by the photovoltaic equipment. When this electrical energy is needed, it is inverted into alternating current through the energy storage converter for use by the load or the grid.

In the photovoltaic industry, there are: centralized, string, and micro inverters

Inverter - DC to AC: The main function is to invert the DC power converted by solar energy into AC power through photovoltaic equipment, which can be used by the load or integrated into the power grid or stored.

Centralized type: applicable to large-scale ground power stations and distributed industrial and commercial photovoltaics, with general output power greater than 250KW.

String type: applicable to large ground power stations, distributed industrial and commercial photovoltaics (generally output power is less than 250KW, three-phase), and household photovoltaics (generally output power is less than or equal to 10KW, single-phase).

Microinverter: The applicable scope is distributed photovoltaics (generally output power is less than or equal to 5KW, three-phase) and household photovoltaics (generally output power is less than or equal to 2KW, single-phase).

PV Inverter and Energy Storage container, its Energy storage systems include: large storage, industrial and commercial storage, household storage, and can be divided into energy storage converters (traditional energy storage converters, Hybrid) and all-in-one machines.

Inverter-AC-DC conversion: The main function is to control the charge and discharge of the battery. The DC power generated by photovoltaic power generation is converted into AC power through the inverter. At this time, part of the electrical energy needs to be stored in the battery, and the energy storage converter needs to be used to convert it. The alternating current is converted into direct current for charging. When this part of the electric energy is needed, the direct current in the battery needs to be converted into alternating current (generally 220V, 50HZ) through an energy storage converter for use by the load or integrated into the power grid. This is discharge. process.

The English name of the energy storage converter is Power Conversion System, or PCS for short. It controls the charging and discharging process of the battery and converts AC to DC power. It is composed of a DC/AC bidirectional converter, a control unit, etc.

Large storage: ground power station, independent energy storage power station, generally the output power is greater than 250KW.

Industrial and commercial storage: Generally, the output power is less than or equal to 250KW.

Household storage: Generally, the output power is less than or equal to 10KW.

Traditional energy storage converter: mainly uses AC coupling scheme, and the application scenario is mainly large storage.

Hybrid: Mainly adopts DC coupling solution, and the application scenario is mainly household savings.

All-in-one machine: energy storage converter + battery pack, the product mainly stores electricity.

With the rapid development of new energy industries such as photovoltaic power generation, equipped with energy storage power stations is the general trend of industry development. Container energy storage power stations adopt an outdoor container integrated design, and energy storage converters, transformers, switch cabinets and other equipment are installed in the containers. , the container system has independent self-power supply system, fire alarm detector, lighting, safety escape system, emergency system and other automatic control and safety systems. Judging from the development history of container energy storage, it is mainly divided into centralized solutions, Centralized and decentralized solutions, and distributed solutions. The differences are as follows:

| Item | Centralized solution | Centralized and decentralized solutions | Distributed solution |

| Energy storage integration | First Generation | second generation | Third Generation |

| principle | Centralized energy storage is the first generation mainstream integration route in the industry. Multiple battery clusters are connected in parallel on the DC side and then combined with BMS, temperature control system, automatic fire protection system and AC and DC power distribution devices to form a battery container. At the same time, in the conversion and voltage boosting part, the PCS and the transformer are combined into a power container, and the two containers are connected through DC cables. | The battery cluster in the battery container is connected to the DC bus through the energy optimizer (DC/DC), and then connected to the grid through the power container composed of PCS + transformer | Through highly integrated battery cluster + PCS + BMS + temperature control fire protection system, an integrated small cabinet is made to systematize the product. The small cabinet method not only breaks away from the limitations of application scenarios, but also enables flexible expansion and solves the problem. Recharge issue. |

| Advantage | Low cost and low technical threshold | Extend battery life | Efficient and reliable, flexible expansion, conversion efficiency higher than 90%, and refined monitoring |

| shortcoming | The whole life cycle cost of electricity is high and the power throughput capacity is low (the core reason is actually the inconsistency of the battery cells), the battery is not fully charged, cannot be fully discharged, and the circulation current is large. | The system cycle efficiency is low, the cost of electricity during the entire life cycle is high, it occupies a large area, and has poor flexibility. It does not support the mixed use of new and old batteries, and it is difficult to replenish power. | High initial investment and low life cycle electricity cost |

| application | Mainly oriented to large-scale energy storage power stations on the source and grid side | Used by large-scale source network side projects | User side + large source network side project use |

| Prospects | The pursuit of optimal investment costs and cost reduction are core factors in technical considerations. The reasons behind this are firstly because the energy storage profit model is not clear, and secondly because most projects are new energy distribution and storage, and many power stations are designed to complete corresponding indicators. | Industry demand has upgraded from “completing distribution and storage indicators” to “how to make profits from energy storage power stations” | Through the high integration of the "product as system" concept and the physical form of a small cabinet |

PV Inverter and Energy Storage Containers are also classified according to the materials used:

1. Aluminum alloy containers: The advantages are light weight, beautiful appearance, corrosion resistance, good elasticity, easy processing, low processing and repair costs, and long service life; the disadvantages are high cost and poor welding performance;

2. Steel containers: The advantages are high strength, firm structure, high weldability, good water tightness, and low price; the disadvantages are heavy weight and poor anti-corrosion properties;

3. Fiberglass containers: The advantages are high strength, good rigidity, large internal volume, good heat insulation, anti-corrosion, and chemical resistance, easy to clean, and simple repairs; the disadvantages are heavy weight, easy aging, and reduced strength at the bolt tightening point.

The design of PV Inverter and Energy Storage containers is mainly divided into two parts

1. Battery compartment: The battery compartment mainly includes batteries, battery racks, BMS control cabinets, heptafluoropropane fire extinguishing cabinets, cooling air conditioners, smoke-sensing lighting, surveillance cameras, etc. The battery needs to be equipped with a corresponding BMS management system.

Battery types can be lithium iron batteries, lithium batteries, lead-carbon batteries and lead-acid batteries. The cooling air conditioner adjusts in real time according to the temperature in the warehouse. Surveillance cameras can remotely monitor the operating status of equipment in the warehouse. A remote client can be formed to monitor and manage the operating status and battery status of the equipment in the warehouse through the client or app.

2. Equipment warehouse: The equipment warehouse mainly includes PCS and EMS control cabinets. PCS can control the charging and discharging process, perform AC and DC conversion, and can directly power AC loads when there is no power grid.

In the application of energy storage systems, the function and role of EMS are relatively important. In terms of distribution network, EMS mainly collects the real-time power status of the power grid through communication with smart meters and monitors changes in load power in real time. Control automatic power generation and evaluate power system status.

In a 1MWh system, the ratio of PCS to battery can be 1:1 or 1:4 (energy storage PCS 250kWh, battery 1MWh).

3. The heat dissipation design of the 1MW container-type converter adopts the design of forward air distribution and rear air discharge. This design is suitable for energy storage power stations where all PCS are placed in the same container. The wiring, maintenance channels and heat dissipation design of the container's internal power distribution system are integrated and optimized to facilitate long-distance transportation and reduce subsequent maintenance costs.

Container energy storage system components

Taking the 1MW/1MWh container energy storage system as an example, the system generally consists of an energy storage battery system, a monitoring system, a battery management unit, a dedicated fire protection system, a dedicated air conditioner, an energy storage converter and an isolation transformer, and is ultimately integrated into a 40-foot inside the container.

Battery system: Mainly composed of battery cells connected in series and parallel. First, more than a dozen groups of battery cells are connected in series and parallel to form a battery box. Then the battery box is connected in series to form a battery string and increase the system voltage. Finally, the battery string is connected in parallel to increase the system capacity. Integrated and installed in the battery cabinet.

Monitoring system: Mainly realizes the functions of external communication, network data monitoring and data collection, analysis and processing to ensure accurate data monitoring, high voltage and current sampling accuracy, data synchronization rate and remote control command execution speed. The battery management unit has a high-precision unit The body voltage detection and current detection functions ensure the voltage balance of the battery modules and avoid circulating current between battery modules, which affects the system operating efficiency.

Fire protection system: In order to ensure the safety of the system, the container is equipped with a dedicated fire protection and air conditioning system.

Fire alarms are sensed through safety equipment such as smoke sensors, temperature sensors, humidity sensors, and emergency lights, and fires are automatically extinguished. The dedicated air conditioning system controls the air conditioning cooling and heating systems through thermal management strategies based on the external ambient temperature to ensure that the temperature inside the container is within the appropriate range and extend the battery life. service life.

Energy storage converter: It is an energy conversion unit that converts battery DC power into three-phase AC power. It can operate in grid-connected and off-grid modes. In grid-connected mode, the converter conducts energy transfer with the grid according to the power instructions issued by the upper-level dispatch. interaction;

In off-grid mode, the energy storage converter can provide voltage and frequency support for factory loads and provide black-start power for some renewable energy sources.

The outlet of the energy storage converter is connected to the isolation transformer to completely insulate the primary side and secondary side electrically, ensuring the safety of the container system to the greatest extent.

Lithium battery container energy storage systems are divided into cabinet energy storage systems and container energy storage systems according to different installation forms.

As energy storage systems shift to longer durations, customers purchasing lithium battery energy storage systems will intensify their demand for energy and power. The lithium battery container energy storage system is based on advanced lithium battery technology and equipped with standardized converter equipment and monitoring and management systems, which can better meet the growing demand for energy storage.

As the demand for electrical energy continues to increase, the requirements for energy efficiency and energy security are also getting higher and higher, so the market demand for energy storage containers is also growing. The energy storage container adopts a modular design and is easy to maintain and upgrade, which can extend the service life of the product and reduce maintenance costs. We cooperate with well-known brands such as Siemens, Emerson, GE, Huawei, etc., and export to the United States, Germany, Australia, Canada, the United Kingdom, France, India, Brazil and other countries. Our products use high-quality materials and strict production processes, with reliable safety and stability, and have passed ISO9001 quality management system certification and CE, ROHS certification. Energy storage containers have many advantages, including high efficiency, energy saving, safety and reliability, and easy maintenance.

The PV Inverter and Energy Storage container dynamic environment monitoring system includes energy storage batteries, battery management systems and dynamic environment monitoring systems, giving full play to product research and development advantages to provide dynamic environment monitoring, fire protection, video monitoring, etc. The energy storage container dynamic environment monitoring system can remotely monitor The power consumption, battery, temperature and humidity, fire protection, video, access control, etc. of the energy storage container; its system configuration is as follows:

1. Single cabinet (supports multiple cabinets):

The energy storage container system consists of "intelligent detection sensors + power environment monitoring host (including management software) + alarm module", which can monitor power distribution, battery packs, air conditioning, temperature and humidity, water leakage, fire protection, smoke, video, door sensors, etc. .

2. Centralized terminal: 24-hour dynamic ring centralized monitoring software

3. Support customized development and secondary development:

The energy storage container system can handle common faults in a timely manner and remind maintenance personnel to take necessary countermeasures to solve the problem, further improving the maintenance effect of the container and improving the reliability and safety factor of the energy storage system operation.

An PV Inverter and Energy Storage container is a sealed container that integrates energy storage batteries, power conversion systems, cooling systems and other equipment. It is an efficient, reliable, safe and intelligent energy storage solution suitable for various outdoor environments, such as power, communications, industrial control and other fields. Advantages of energy storage containers:

1. Multiple protection: Energy storage containers have good anti-corrosion, fire-proof, waterproof, dust-proof (anti-sand), shock-proof, anti-ultraviolet, anti-theft and other functions, and are guaranteed to be free from corrosion within 25 years.

2. Safety and flame retardant: The container shell structure, heat insulation materials, internal and external decoration materials, etc. all use flame retardant materials.

3. Strong adaptability: The energy storage container has a simple and beautiful appearance. It adopts a fully enclosed box design with good sealing performance. It can not only adapt to various outdoor environments, such as working in harsh environments such as high temperature, low temperature, humidity, rain and snow, but also has a ventilation filter to isolate dust, good sound insulation effect, and low pollution.

4. Anti-shock function: It must be ensured that the mechanical strength of the container and its internal equipment meets the requirements under transportation and earthquake conditions, and that there will be no deformation, abnormal function, or failure to operate after vibration.

5. Anti-ultraviolet function: It must be ensured that the properties of materials inside and outside the container will not deteriorate due to ultraviolet irradiation, and will not absorb ultraviolet heat, etc.

6. Anti-theft function: It must ensure that the container will not be opened by thieves in outdoor open conditions. It must ensure that a threatening alarm signal is generated when a thief attempts to open the container. At the same time, an alarm is sent to the background through remote communication. This alarm function can be controlled by User blocking.

7. Modular design: The container standard unit has its own independent power supply system, temperature control system, heat insulation system, flame retardant system, fire alarm system, mechanical interlocking system, escape system, emergency system, fire protection system and other automatic control and support systems. .

8. Wide application: Energy storage containers are generally used in large-scale infrastructure projects such as power construction, medical emergency, petrochemical industry, mining and oil fields, hotels, vehicles, highways and railways. Energy storage containers are preferred for power supply because they are efficient and convenient.

9. Easy installation: Compared with traditional fixed energy storage power stations, it is difficult to select a location, depends on terrain, has a long investment cycle, and has large losses; the energy storage container is not restricted by geography, has strong environmental adaptability, allows sea transportation and road transportation, and is easy to hoist by crane. Easy to install.

10. Low operation and maintenance costs: As energy storage applications become more mature in the future, more and more factories and parks will tend to invest in the construction of energy storage power stations, peak shaving and valley filling, and demand management. Energy storage containers can greatly save project construction and operation and maintenance costs. Coupled with unique advantages such as large development volume, high safety and reliability, small impact on the environment, and wide range of applications, they will definitely receive more favor and expectations.

11. Intelligent control: Equipped with an intelligent control system, it can realize remote monitoring and control, facilitate user management and maintenance, and also supports 1000V+ high-voltage systems.

12. Customizable: Energy storage containers can be customized according to different needs and application scenarios to achieve diversified applications, such as power backup energy storage, mobile energy, etc.

To sum up, energy storage containers have the characteristics of high efficiency, reliability, safety, adaptability, intelligent control and customization. They are suitable for various outdoor environments and provide reliable solutions for energy storage and utilization.

Application fields: energy storage power station, microgrid, grid frequency regulation, peak shaving and valley filling, backup power,etc.

- View as

Deep Cycle GEL Battery

As the number of battery customers around the world continues to increase, many customers report that due to unstable power supply during the day and short mains power hours, the battery power is consumed very quickly and cannot be fully charged, resulting in a shortened battery life and the need for frequent replacement. This is because if the battery is deeply discharged at night and cannot be fully charged during the day, the battery will sulfate after a few months of operation and the capacity will decrease rapidly, causing the battery to lose power quickly.

To this end, our R&D personnel have specially developed a tubular deep cycle gel battery, using tubular plates to replace the old plate design, which improves the utilization of the plates. Even if the battery is not fully c......

Polycrystalline Solar Panel

The manufacturing process of polycrystalline solar panel is similar to that of monocrystalline silicon solar panels, but the photoelectric conversion efficiency of polycrystalline solar panels is much lower, and its photoelectric conversion efficiency is about 12%. In terms of production cost, it is lower than monocrystalline silicon solar panels. The material is easy to manufacture, saves power consumption, and the overall production cost is low, so it has been widely developed.

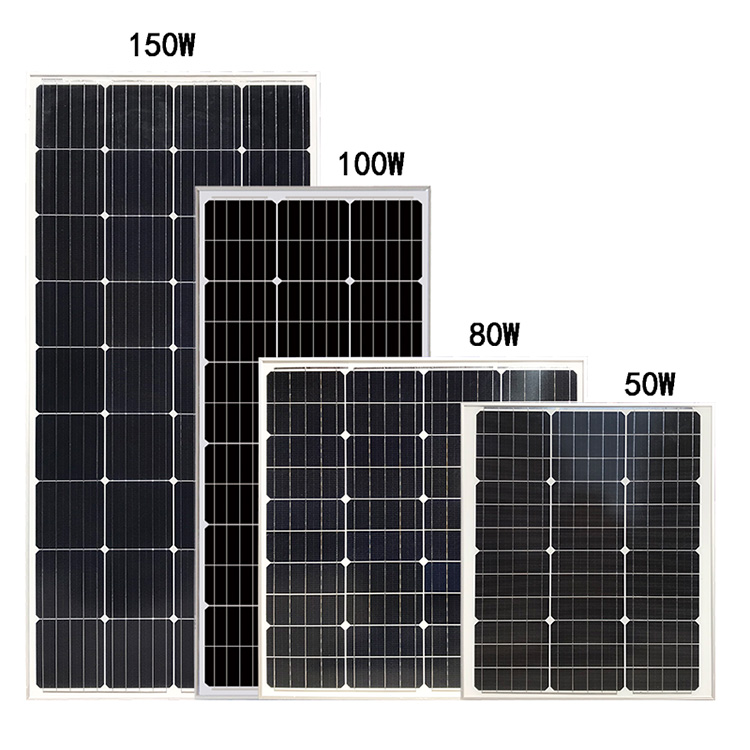

Read MoreSend InquiryMonocrystalline Solar Panel

CPSY® Monocrystalline solar panels are assembled from monocrystalline silicon solar cells on a board in a specific connection method. When solar panels are illuminated by sunlight, the light radiation energy is directly or indirectly converted into electrical energy through the photoelectric effect or photochemical effect. Compared with traditional power generation, solar power generation is more energy-saving and environmentally friendly. Monocrystalline silicon solar cells have the highest conversion efficiency and the most mature technology.

Read MoreSend Inquiry12.8V LiFePO4 Battery

The CPSY® 12.8V LiFePO4 battery with built-in BMS is designed as a deep cycle discharge battery pack, providing solutions for demanding applications requiring lighter, longer life and higher capacity batteries, and features advanced battery management system (BMS) and Bluetooth smart monitoring. 4P4S connection is available to expand capacity and voltage. Widely used in communication power systems, UPS systems, off-grid or micro-grid systems, security and protection systems, emergency lighting power supplies, portable medical equipment, golf carts, RVs, solar/wind energy systems, remote monitoring, etc. and how to quickly charge large capacities or high voltage power equipment.

Read MoreSend Inquiry