- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

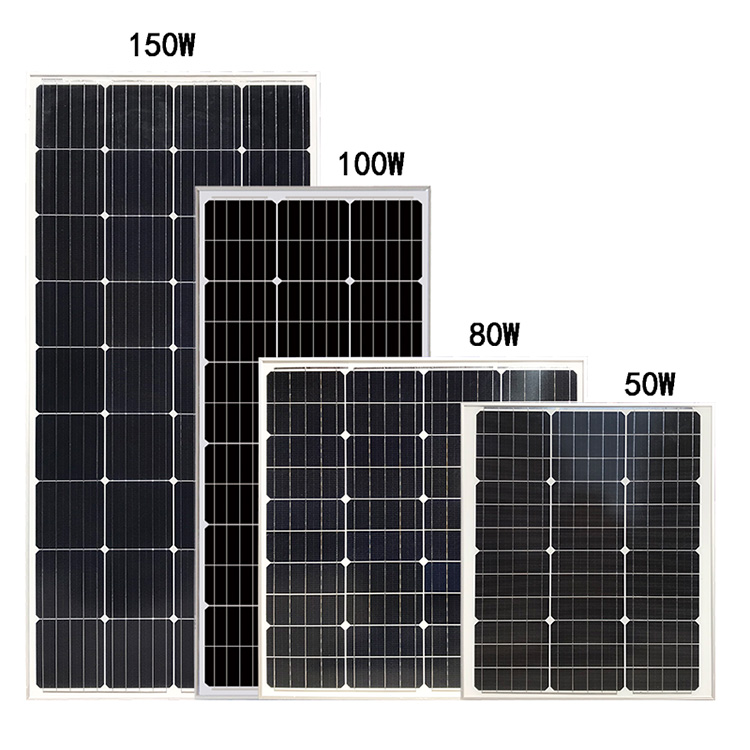

Polycrystalline Solar Panel

The manufacturing process of polycrystalline solar panel is similar to that of monocrystalline silicon solar panels, but the photoelectric conversion efficiency of polycrystalline solar panels is much lower, and its photoelectric conversion efficiency is about 12%. In terms of production cost, it is lower than monocrystalline silicon solar panels. The material is easy to manufacture, saves power consumption, and the overall production cost is low, so it has been widely developed.

Send Inquiry

Polycrystalline solar panels are assembled from polycrystalline silicon solar cells on a board in a specific connection method. When solar panels are illuminated by sunlight, the light radiation energy is directly or indirectly converted into electrical energy through the photoelectric effect or photochemical effect. Compared with traditional power generation, solar power generation is more energy-saving and environmentally friendly, with simple manufacturing process and lower cost. Its production process is divided into silicon wafer inspection - surface texturing - diffusion knotting - dephosphorization of silicate glass - plasma etching - anti-reflective coating - --Screen printing----Fast sintering, etc. Polycrystalline solar panel, polycrystalline solar panel, ultra-white cloth pattern tempered glass. The thickness is 3.2mm and the light transmittance is over 91%.

CPSY® Polycrystalline solar panel Parameter (Specification)

| Capacity | Power Tolerance(%) | Open Circuit Voltage(voc) | Max. Voltage(vmp) | Short Circuit Current(Isc) | Max.Current(lmp) | Module Efficiency |

| 50W | ±3 | 21.6V | 17.5V | 3.20A | 2.68A | 17% |

| 100W | ±3 | 21.6V | 17.5V | 6.39A | 5.7A | 17% |

| 150W | ±3 | 21.6V | 17.5V | 9.59A | 8.57A | 17% |

| 200W | ±3 | 21.6V | 17.5V | 12.9A | 11.0A | 17% |

| 250W | ±3 | 36V | 30V | 9.32A | 8.33A | 17% |

| 300W | ±3 | 43.2V | 36V | 9.32A | 8.33A | 17% |

CPSY®Polycrystalline solar panel Feature And Application

Features:

1. Made of ultra-white textured tempered glass with a thickness of 3.2mm, within the wavelength range of the solar cell spectral response (320-1100nm), it is resistant to aging, corrosion, and ultraviolet radiation, and the light transmittance does not decrease.

2. Components made of tempered glass can withstand the impact of an ice ball with a diameter of 25 mm at a speed of 23 meters/second, and are strong and durable.

3. Use a high-quality EVA film layer with a thickness of 0. 5mm as the sealant of the solar cell and the connecting agent with glass and TPT. It has a high light transmittance of more than 91% and anti-aging ability.

4. The aluminum alloy frame used has high strength and strong resistance to mechanical impact.

5. Encapsulated using tempered glass and waterproof resin, the service life can reach 15-25 years, and the efficiency will be 80% after 25 years.

6. Photoelectric conversion efficiency is about 12-15%

7. The amount of waste silicon is small, the manufacturing process is simple and the cost is lower

Performance requirements after curing of EVA film for solar cell packaging: light transmittance greater than 90%; cross-linking degree greater than 65-85%; peel strength (N/cm), glass/film greater than 30; TPT/film greater than 15; Temperature resistance: high temperature 85℃, low temperature -40℃.

solar panels raw materials: glass, EVA, battery sheets, aluminum alloy shells, tin-coated copper sheets, stainless steel brackets, batteries and other new coatings have been successfully developed.

Applications:

Off-grid power supply for cabins, vacation homes, travel RVs, campers, remote monitoring systems

Solar energy applications such as solar water pumps, solar refrigerators, freezers, televisions

Remote areas with insufficient power supply

Centralized power generation in power stations

Solar buildings, home roof grid-connected power generation systems, photovoltaic water pumps

Photovoltaic systems and power systems, base stations and toll stations in the field of transportation/communication/communications

Observation equipment in the fields of petroleum, ocean and meteorology, etc.

Home lighting power supply, photovoltaic power station

Other fields include supporting automobiles, power generation systems, power supply for desalination equipment, satellites, spacecraft, space solar power stations, etc.

CPSY® Polycrystalline solar panel Details

The differences between monocrystalline solar panels, polycrystalline solar panels and thin film solar panels are as follows:

| Item | Monocrystalline solar panels | Polycrystalline solar panels | thin film solar panel |

| Conversion efficiency | High, 15%-24% | Medium, 12%-15% | Low, 7-13% |

| price | high | middle | Low |

| Material | Mainly silicon, boron and phosphorus layers | Mainly silicon, boron and phosphorus layers | Cadmium Telluride (CdTe)/Amorphous Silicon (a-Si)/Copper Indium Gallium Selenide (CIGS) |

| Exterior | Beautiful and beautiful | Slightly variegated | Thin, transparent and bendable |

| application | Key places, even power plants, space, etc. | Mostly for home use | Temporary places, mostly used outdoors |

| encapsulation | Encapsulated with epoxy resin or PET | Encapsulated with tempered glass and waterproof resin | Available in glass or stainless steel |

| Transmittance | More than 91% | 88-90% or more | above 50 |

| Arrangement | Regular serial-parallel array method | irregular array | - |

| Production Process | The Siemens method improves the Czochralski method to manufacture silicon wafers and then assembles them into modules. | Silicon wafers are manufactured by casting method and then assembled into modules | Using printing technology and thin film deposition technology |

| Service life | 20-25 years or more | 15-25 years or more | More than 15-20 years |

Power calculation method

The solar AC power generation system is composed of solar panels, charge controller, inverter and battery; the solar DC power generation system does not include the inverter. In order for the solar power generation system to provide sufficient power for the load, each component must be reasonably selected according to the power of the electrical appliance. The following takes 100W output power and 6 hours of use per day as an example to introduce the calculation method:

1. First, calculate the number of watt hours consumed every day (including the loss of the inverter): If the conversion efficiency of the inverter is 90%, then when the output power is 100W, the actual required output power should be 100W/90 %=111W; If used for 5 hours a day, the power consumption is 111W*5 hours=555Wh.

2. Calculate the solar panel: Based on the effective daily sunshine time of 6 hours, and taking into account the charging efficiency and loss during the charging process, the output power of the solar panel should be 555Wh/6h/70%=130W. 70% of this is the actual power used by the solar panel during the charging process.

RFQ

1. What are the classifications of solar panels?

--- According to crystalline silicon panels, they are divided into: polycrystalline silicon solar cells and monocrystalline silicon solar cells.

---Amorphous silicon panels are divided into: thin film solar cells and organic solar cells.

--- According to chemical dye panels, they are divided into: dye-sensitized solar cells.

2. How to distinguish monocrystalline, polycrystalline and amorphous solar panels?

Monocrystalline solar panels: no pattern, dark blue, almost black after encapsulation,

Polycrystalline solar panels: There are patterns, polycrystalline colorful and polycrystalline less colorful, like the light blue snowflake crystal pattern on the snowflake iron sheet.

Amorphous solar panels: Most of them are glass and brown in color

3. What are solar panels?

Solar panels capture the sun's energy and convert it into electricity. A typical solar panel consists of individual solar cells made up of layers of silicon, boron and phosphorus. Positive charges are provided by the boron layer, negative charges are provided by the phosphorus layer, and the silicon wafer acts as a semiconductor. When photons from the sun strike the panel surface, they knock electrons out of the silicon and into the electric field created by the solar cell. This creates a directional current that can then be converted into usable power, a process called the photovoltaic effect. A standard solar panel has 60, 72 or 90 individual solar cells.

3.The difference between monocrystalline and polycrystalline solar cells

1)Different characteristics Polycrystalline silicon solar cells: Polycrystalline silicon solar cells have the characteristics of high conversion efficiency and long life of monocrystalline silicon cells and the relatively simplified material preparation process of amorphous silicon thin film cells.

2)Difference in appearance. From the appearance, the four corners of monocrystalline silicon cells are arc-shaped and have no patterns on the surface; while the four corners of polycrystalline silicon cells are square and have patterns similar to ice flowers on the surface.

3)The speed of polycrystalline silicon solar panels is generally two to three times that of monocrystalline silicon, and the voltage must be stable. The manufacturing process of polycrystalline silicon solar cells is similar to that of monocrystalline silicon solar cells, and the photoelectric conversion efficiency is about 12%, which is slightly lower than monocrystalline silicon solar cells.

4)Different photoelectric conversion rates: The maximum conversion efficiency of monocrystalline silicon cells in the laboratory is 27%, and the conversion efficiency of ordinary commercialization is 10%-18%. The maximum efficiency of polycrystalline silicon solar cells in the laboratory reaches 3%, and the general commercial efficiency is generally 10%-16%.

5)The interior of a single-crystal silicon wafer is composed of only one crystal grain, while a multi-crystal silicon wafer is composed of multiple crystal grains. The conversion efficiency of monocrystalline silicon wafers is higher than that of polycrystalline silicon wafers, generally more than 2% higher, and of course the price is higher.

6)There is no difference between monocrystalline and polycrystalline in terms of battery panels and use. But there are differences in production and photoelectric conversion efficiency. Monocrystalline solar cells use monocrystalline silicon as raw material. The surface is mostly blue-black or black, and the crystal structure cannot be seen.